Glass & Glazing Products

Glass is a beautiful material. It is versatile and functional. Architects, interior designers and consumers specify glass for many uses, because it lets light into your home, promises clear vision, and of course, it is easily cleaned. Glass processing transforms raw sheets of glass into high-performance products.

By cutting, toughening, laminating, decorating or polishing and incorporating processed glass into sealed units, glass can now be used to provide safety, security, passive solar control, thermal and acoustic insulation. There are many different glasses available on the market today for all kinds of applications.

Types of Glass

- Float/ Annealed Glass

- Toughened Glass

- Laminated Glass

- Energy Saving Glass

- Vacuum Glazing

- Technical Glass

- Fire Resistant Glass

- Wired Glass

- Custom Fitted Cat Flaps

- Decorative and Restoration Glass

The Starting Point Is Float/Annealed Glass

This high quality, transparent flat glass is manufactured by floating molten glass on a ‘tin bath’ at an extremely high temperature. The glass is then gently cooled to enable cutting and further processing of the glass post manufacture. Float/Annealed Glass is the starting point for all other glasses to be manufactured and processed.

Patterned and Textured Obscure Glass. During the manufacture process of Float/Annealed Glass the patterns are printed into the glass

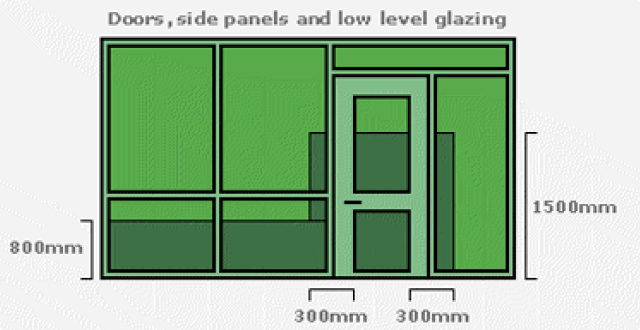

Critical Locations

Since 1992 there has been a requirement in the England & Wales Building Regulations for robust or protected glazing in certain critical locations. This means the glass must either break safely, resist impact or be protected from impact by permanent guarding. Where Doubled Glazed Units are provided both sheets of glass will need to conform if people are likely to come into contact with the glass from either side (e.g. patio doors).

All tempered (i.e. toughened) or laminated glass must (with minor exceptions) be marked in accordance with BS6206.

Homeowners are becoming increasingly aware about safety in their homes and visible etched markings on all panes is the only evidence of complying with British Standards BS6206.The diagram below shows the dark shaded areas as those requiring safety glass.

Small panes of 6mm annealed glass are suitable in critical locations if the area of the single pane is no more than 0.5m2 and the width of each pane is no more than 250mm.

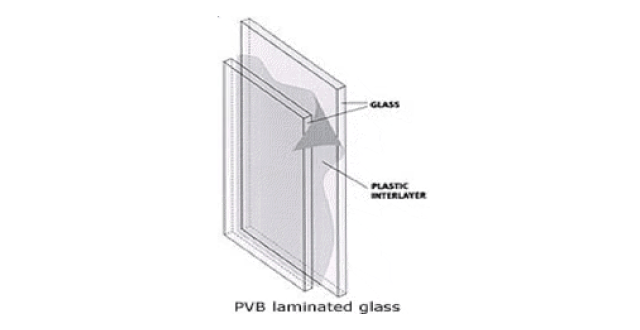

Laminated Glass

Manufactured by assembling two panels of glass which are sandwiched together with PVB. This is, therefore, a composite high performance product which combines the material properties of the glass with the unique properties of PVB such as adhesion to glass, elasticity and impact resistance.

This glass is particularly suitable where it is important to ensure the resistance of the whole sheet after breakage such as: Shop-Fronts, Balconies, Stair-Railings and Roof Glazing.

Laminated glass can have electricity passed between the two panes of glass to make it activate an alarm, to heat the glass and to switch the glass from clear to opaque.

All installed safety glass should be clearly marked with the British Standard test reference BS6206, with the letter L for laminated, and T for toughened, together with the company registration number of the supplier.

Toughened Glass

Achieved by heating annealed glass to approx 620°C within a furnace at which point it begins to soften, this is then cooled rapidly. When broken, Toughened Glass fractures into small pieces (called dice). As these particles do not have sharp edges and dagger points of normal broken glass it is generally regarded as Safety Glass.

Toughened Glass must be cut to a size and have any other processes (drilling, polishing etc.) completed before toughening because attempts to ‘work’ the glass after will cause it to shatter.

All installed safety glass should be clearly marked with the British Standard test reference BS6206, with the letter L for laminated, and T for toughened, together with the company registration number of the supplier.

Self-Cleaning, Low Maintenance Glass

A transparent coating applied onto the outside surface of the glass harnesses the power of both the sun and rain to efficiently remove dirt and grime such as dried water marks, dust, resin and insect residues. It will always be easier to clean and it will stay cleaner for longer. It is an excellent choice for areas of glazing that are hard to reach.

Self-cleaning glass can be glass that has the transparent coating applied during manufacture or we can apply a ClearShield Ritec Coating to the glass prior to glazing.

Fire Resistant Glass And Anti-bandit Glass

Fire Resistant glass has a metallic coating applied to it to achieve 30,60 or 90 minute resistance. If the glass is also Laminated 120minute resistance can be achieved because, during a fire the PVU inter-layers expand to form an opaque barrier.

Anti-bandit glass is composed of multi layers of glass and a corresponding number of PVU inter-layers. The inter-layers must have a minimum thickness of 1.52mm. Basically the thicker the overall thickness the stronger it is.

Wired Glass

Wired glass is a clear or slightly textured glass incorporating a metal lattice of 12.5mm squares. Used as a single pane of glass it can provide some fire resistance. It is used in many applications, including overhead glazing, canopies, entrance doors, windows, interior partitions, etc.

Wired glass may be used as part of a double glazed unit.

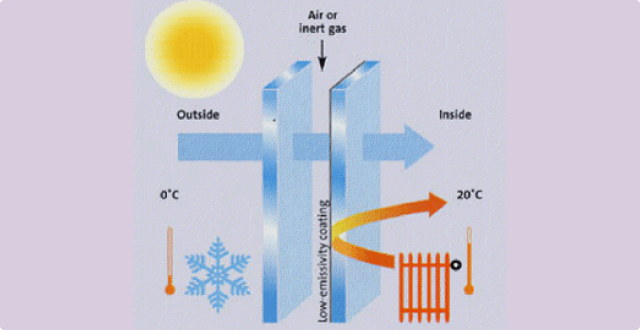

Low-e Energy Saving Glass Can Only Be Used For Glazing As Part Of A Double Glazed Unit.

Low E Energy Saving Glass is designed to help insulate your home by keeping as much heat inside as possible. Low E Energy Saving Glass has a transparent metallic coating on one side that reflects heat back into the room rather than allowing it to escape through the window. It also allows optimum amounts of sunlight to pass through the window.

There are two choices of Low E Energy Saving Glass, these are called Hard Coat and Soft Coat. They both perform the same job but the soft coat has better thermal insulation, therefore reducing heat loss even further. The inner surface of the glass stays warmer thereby reducing the likelihood of condensation. And there is less of a yellowish tint or dusty appearance to the glass.

Mirrors

Mirror comes in 4mm and 6mm thickness and is made to measure either to your sizes or to a template. Edges can have polished edges or have a sloping bevelled edge to give a framed appearance. Mirrors can be drilled and internal shapes can be cut out and are installed by screwing to the wall using chrome domehead screws or corner brackets or we can stick them onto a wall using a specialist mirror adhesive.

Safety backing can be applied to mirror glass to prevent any shards or pieces of glass falling if the mirror was to crack, smash or shatter. Safety backing is often a safety regulation or requirement in schools, hospitals and other public places

Downloads GGF Laminated And Toughened Glass Advice Below

GGF Laminated Glass Guide

GGF Toughened Glass Guide

Let’s get in touch

Contact CN Glass today to arrange a quotation. Reach us in the following options.

Address:

Norton House, Beaumont Road

Banbury, Oxfordshire OX16 1SD

Phone Number:

"*" indicates required fields